Infrastructure & Manufacturing

At United Timber Works, we pride ourselves on our state-of-the-art digital infrastructure, designed to provide unparalleled convenience and transparency to our valued clients. Here’s how we leverage technology to elevate your experience:

Digital Order to Delivery Tracking: Our robust system enables real-time tracking of orders from placement to delivery, ensuring transparent communication and efficient logistics management.

Comprehensive Complaint Responses Tracking: With our advanced tracking system, every query or issue from our dealers is promptly addressed and resolved, setting new benchmarks for customer service efficiency.

Integrated Digital Checklists: Throughout production and sales, our materials undergo meticulous scrutiny, passing through 73 checkpoints meticulously monitored through digital checklists. This ensures that every product meets our rigorous quality standards before reaching your doorstep.

With our cutting-edge digital infrastructure, we guarantee a seamless, hassle-free experience, empowering you to focus on your projects with confidence.

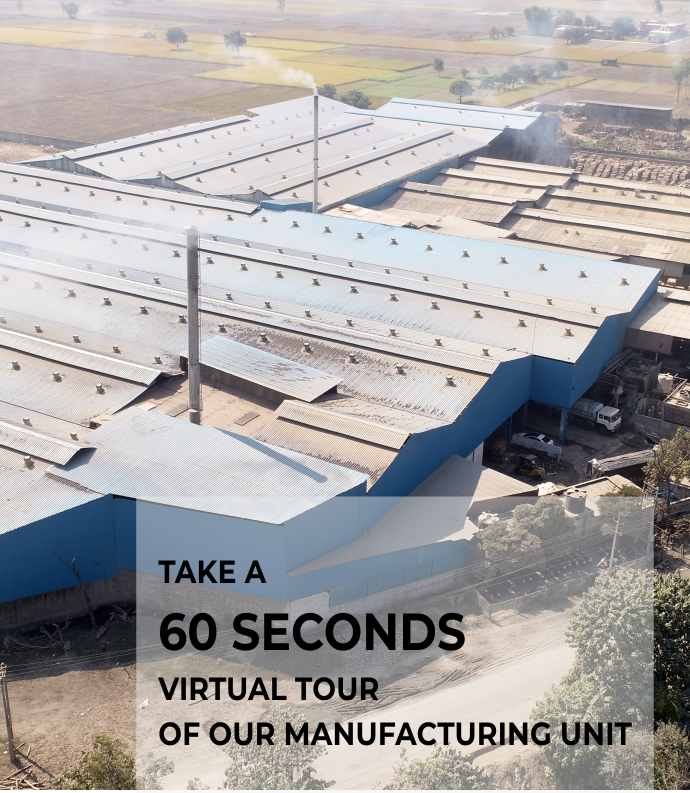

Welcome to our state-of-the-art manufacturing facility, where precision meets innovation to deliver top-notch products for our clients. Here’s a glimpse into our machinery infrastructure:

1.)Sprawling across 8.5 acres, our fully automated manufacturing facility operates seamlessly to ensure efficiency and quality in every step of production.

2.)Our cutting-edge thermic and steam boiler house is fully automated, guaranteeing optimal temperatures essential for the manufacturing process of waterproof shuttering plywood.

3.)Equipped with 3 32-daylight high-density automated hot presses, we have the capacity to handle large-scale production while maintaining uniformity and precision in our products.

4.)Proudly housing India’s largest veneer dryers, we ensure the thorough drying of veneers, enhancing their durability and stability for superior end products.

5.)With six fully automated veneer peeling lines, we possess the capability to produce high-quality veneers with speed and accuracy, meeting the needs of our clients.